News

The Data Advantage: Using HydraTune Insights for Smarter Maintenance

December 4, 2025

Blogs

Hydraulic maintenance has always carried a mix of risk, pressure and deadlines. Many teams focus on completing the task safely and efficiently, yet the information behind every adjustment often goes unused. HydraTune changes this by turning each tuning session into a source of insight. Every pressure change, every valve movement and every operator input becomes part of a growing data set that can help teams better understand system behaviour.

Capturing Real-Time Data That Builds a Clearer Picture

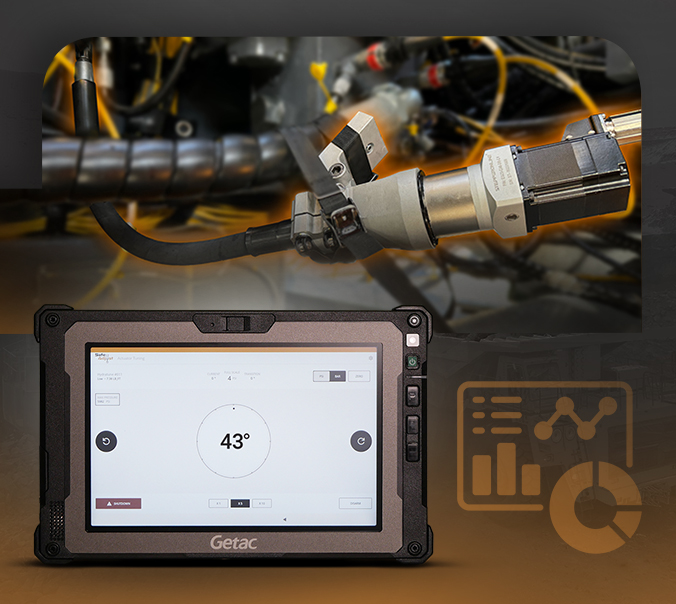

We’ve already discussed in a previous blog how SafeAdjust helps protect technicians. But what it also does is it provides maintenance teams with live system readings while tuning takes place. Values such as pressure, valve position and adjustment response appear directly on the tablet. All these readings are automatically recorded. That means that every session produces data that can be reviewed at any time. With that data, technicians can get better visibility into how each component behaves under load or during fine adjustments.

Over longer periods, the data that you collect forms a performance history that can highlight patterns that would be difficult to detect through manual work alone. Small variations in pressure or drift in valve position can point to early signs of wear. Subtle shifts that might be dismissed during manual tuning become easier to recognise when they appear consistently in logged data.

Building Predictive Maintenance Around Real Patterns

Many maintenance strategies still rely on scheduled intervals or reactive repairs. HydraTune helps by providing a proactive strategy which helps identify issues before they escalate. With each tuning session, you get a steady stream of information that can reveal how quickly a component is drifting or how often re-adjustments are needed. Having this type of information allows planners to decide when it’s best to intervene, which in turn, helps reduce downtime and strengthens overall equipment reliability.

Improving Safety and Supporting ELW Through Recorded Insight

Many operations are now under greater scrutiny regarding hazardous energy management. Elimination of live work is becoming a stronger expectation throughout Australia and regulators increasingly look for proof that sites are removing exposure completely, rather than just managing it. HydraTune provides an automatic record of every adjustment, which helps safety teams show that high-risk maintenance doesn’t have to be carried out near pressurised components.

Through ELW and SafeAdjust, each maintenance log contains details such as the adjustment value, the system response and the technician’s actions. These records become valuable during audits because they show that field teams are completing maintenance remotely and consistently. This also helps safety managers identify improvement areas, confirm that ELW principles are being followed and show measurable reductions in exposure hours. The data provides a proof for showing compliance progress without adding administrative burden to already busy teams.

Using Insights to Strengthen Decision-Making Across Operations

Many organisations want to improve reliability but struggle to find clear starting points. HydraTune offers a practical way to build better maintenance strategies by providing insights that reflect real operating conditions. Teams can track how each asset responds across seasons, shifts and work cycles. Patterns that were previously unseen come to light when similar adjustments appear across the same machine type or within a specific part of the fleet. This information can guide broader operational decisions.

With HydraTune: Planners are able to compare the performance of different machine groups.

Supervisors can pinpoint which parts or equipment cause the most downtime.

Procurement teams can make more informed decisions about components or upgrades.

Technicians gain confidence because they can see concrete data on how their adjustments influence performance.

And lastly, the organisation will also benefit from greater transparency, which strengthens both safety and productivity.

A Maintenance Environment Built Around Knowledge

Hydraulic systems will always require careful attention and maintenance crews will always play a critical role in keeping operations moving. HydraTune removes the live work exposure during hydraulic tuning, providing a structured, data-supported approach that helps sites modernise the way they manage maintenance.

HydraTune gives teams the information they need to anticipate problems, tune with accuracy and make better decisions at every level of the organisation. The combination of wireless tuning, universal access and clear data helps create a safer, more consistent and more informed maintenance culture that supports the future of mining and heavy industry.